Description

Key Features of EPS Sandwich Panels for Prefab Construction & Cold Rooms.

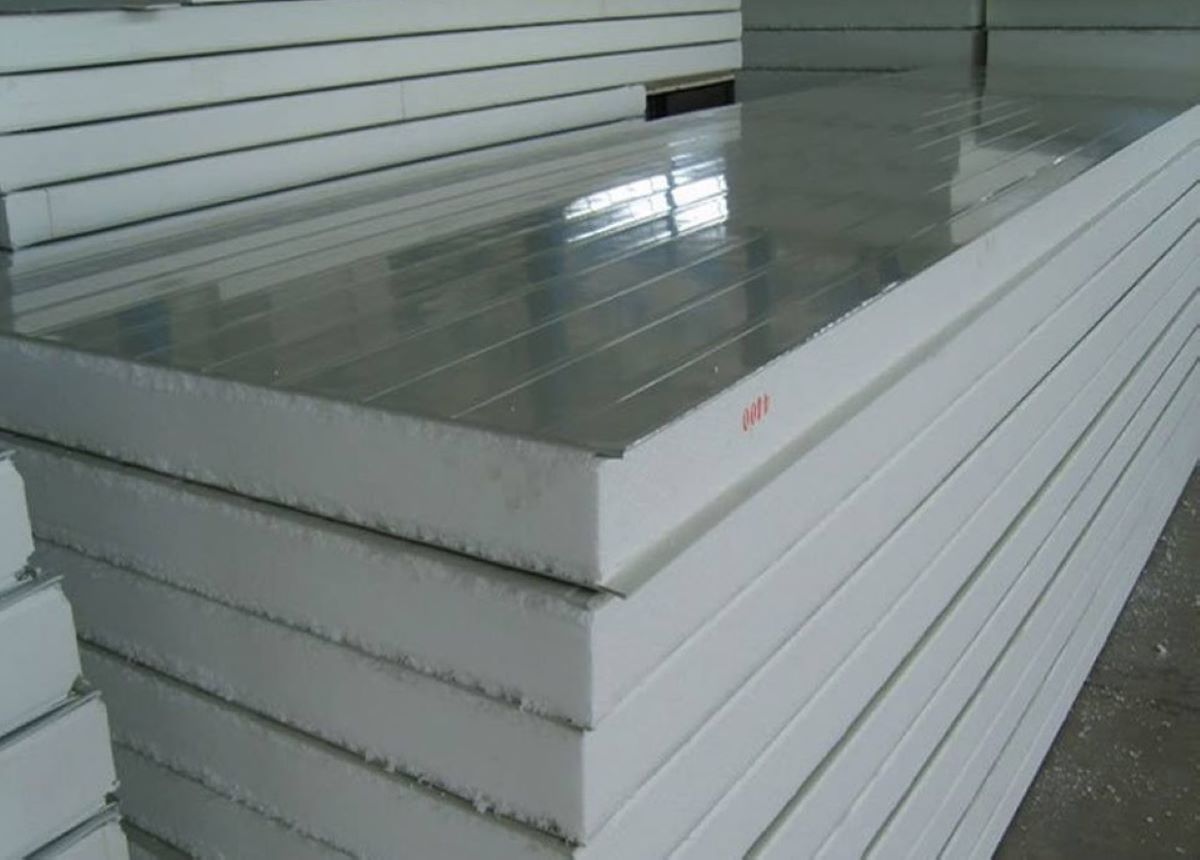

- Core Material:

- Expanded Polystyrene (EPS) core with excellent thermal insulation and soundproofing properties.

- Outer Layers:

- Pre-painted galvanized steel (PPGI), aluminum, or stainless steel for durability, corrosion resistance, and aesthetic appeal.

- Thermal Performance:

- Low thermal conductivity ensures high energy efficiency, reducing heating and cooling costs.

- Lightweight Construction:

- Easy to transport and install, reducing labor and structural support requirements.

- Customization Options:

- Available in various thicknesses, sizes, and colors to suit diverse applications.

- Fire Resistance:

- Optional fire-rated versions with enhanced safety properties.

- Water and Moisture Resistance:

- Designed to resist water infiltration, making them ideal for humid environments.

Its Applications

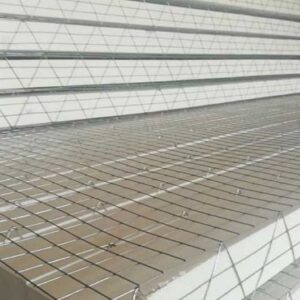

- Construction:

- Prefabricated buildings, warehouses, cold rooms, and modular homes.

- Roofing and Cladding:

- Used for exterior and interior wall panels and roofing systems.

- Insulation:

- Provides thermal insulation for industrial and residential spaces.

- Cold Storage:

- Essential for cold rooms, refrigerated trucks, and storage units.

- Partition Walls:

- Effective in creating soundproof and thermally insulated partitions.

Advantages of EPS Sandwich Panels

Advantages of EPS Sandwich Panels

- Cost-Effective:

- Reduces material and labor costs while providing high functionality.

- Eco-Friendly:

- Energy-efficient and recyclable, contributing to sustainable construction.

- Durability:

- Resistant to wear, weather, and environmental impacts, ensuring a long lifespan.

- Quick Installation:

- Pre-fabricated design speeds up construction timelines.

- Versatility:

- Suitable for a wide range of applications across industries.